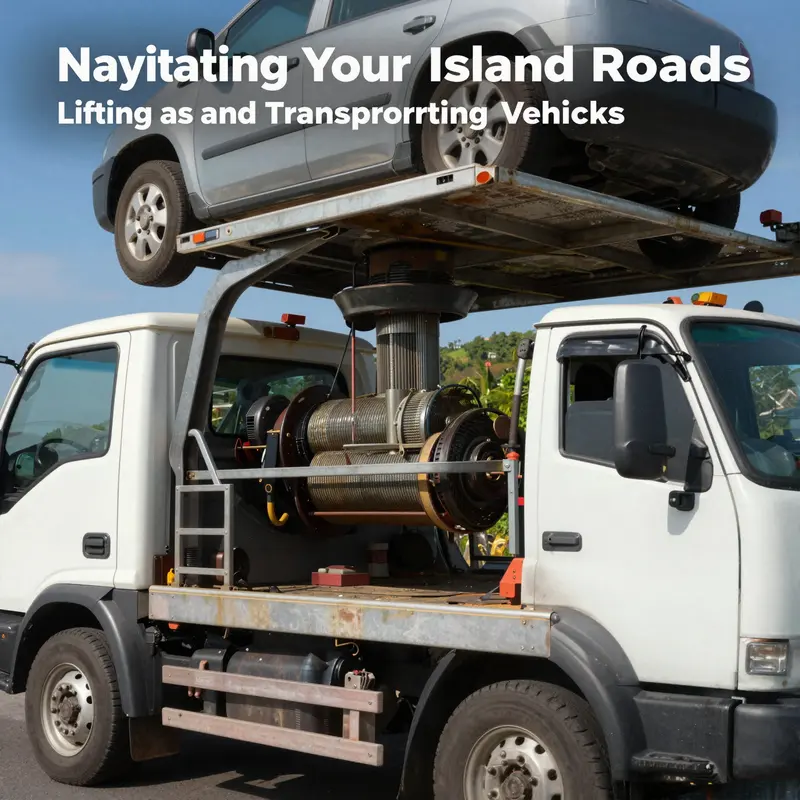

Towing trucks are often the unsung heroes of our island roads, providing crucial support to auto repair shops, car dealerships, property managers, resort operators, and commercial fleet operators. As vehicles traverse various terrains, the potential risks and emergencies they face require reliable towing solutions. This article explores the capabilities of towing trucks, delving into their lifting and transporting abilities, the stringent safety standards and environmental compliance they uphold, and their pivotal role in roadside assistance and emergency services. Each chapter highlights these facets, demonstrating how towing trucks enhance service delivery and safety on the islands, ultimately reinforcing the essential nature of these vehicles in our communities.

null

null

Toward Safer Roads and Cleaner Recoveries: Safety Standards and Environmental Compliance for Modern Towing Trucks

A towing truck sits at a tense crossroads between immediate roadside necessity and long-term responsibility. It is called into service when normal traffic asserts its own gravity, when vehicles broken on the shoulder or involved in a collision must be brought back into the flow of the road with both speed and care. In this demanding role, safety standards and environmental compliance are not mere formalities; they are the foundation of trust between operators and the public, the guarantee of worker safety, and the safeguard for the thousands of engines, tires, and suspensions that encounter tow operations every day. In the Malaysian context, this balance has grown more complex as regulators have updated technical standards to reflect advances in equipment, a deeper understanding of operational risk, and a growing emphasis on environmental stewardship. The changes redirected attention from simply having the right gear to making sure that gear works reliably, transparently, and with a minimal footprint, even when the clock is ticking and the scene is chaotic.

To appreciate the current landscape, one must first consider the core logic of roadworthy tow trucks. Inspections are not a ritual; they are a practical assurance that the chassis, hydraulics, winches, cranes, and flatbeds can perform under load, under pressure, and under the unpredictable dynamics of a live traffic environment. Since November 2023, the latest round of technical standards in Malaysia has reinforced that this roadworthiness is not static. It requires ongoing verification that the vehicle remains compliant with evolving guidelines, that components subject to wear—such as hydraulic hoses, winch drums, and strap anchors—are replaced or rehabilitated before they fail, and that safety systems function as designed. The inspection regime is therefore not a single checkpoint but a continuous state of preparedness, aligning the tow truck with a broader culture of safety that extends to the operators behind the wheel and the technicians who service the fleet.

Equipment standards within this framework touch the most visible aspects of the tow operation and the most critical ones. General equipment, by itself, is not a guarantee of safety; it is a system of interlocked capabilities that must work in harmony. The securing devices, for example, are not just straps and chains; they are precision tools whose ratings, attachment points, and locking mechanisms must withstand the forces generated when a vehicle is pulled onto a bed or restrained during recovery on a busy highway. Properly used, securing devices prevent uncontrolled movement that could injure workers or cause a secondary collision. Vehicle signage plays a double role: it informs other road users that a tow operation is underway and it communicates, through standardized markings, the specific approach the crew will take to secure, lift, or transport a vehicle. Lights and warning systems do the same work in the dark hours and in low-visibility conditions, ensuring that passing motorists can anticipate and space themselves safely, reducing the risk of incidents that chain-react through a congested scene.

The classification and limitations a regulator assigns to heavy vehicles in tow operations are not cosmetic labels. They shape everything from permissible payloads to the allowable configurations for winches and booms, and they influence how crews conduct lifts, transfers, and rollback maneuvers. Operators must understand the boundaries, for exceeding them can invite structural stress, tire failure, or catastrophic accidents. This is why the standards emphasize not only what a tow truck is permitted to do, but how it is permitted to do it under real-world conditions, including road grade, weather, traffic density, and the integrity of the vehicle being recovered. The objective is not to curb capability but to align capability with predictable, controllable outcomes.

Environmental compliance has moved from a peripheral concern to a central design principle. Designers and operators recognize that a tow truck is part of a broader ecosystem, one where fuel use, emissions, noise, and material lifecycle matter just as much as the speed with which a vehicle can be recovered. Modern tow trucks increasingly incorporate features that improve recovery efficiency while reducing environmental impact. Multi-speed winches, for instance, offer smoother control over load handling and can conserve fuel by optimizing engine and hydraulic performance during long or difficult recoveries. Stabilization struts, beyond their role in stabilizing a vehicle during a lift, contribute to safer operations with less abrupt engine load fluctuations, which translates into more efficient fuel use and lower emissions over a recovery cycle. Flatbed tow trucks, often preferred for certain types of recoveries, support a design ethos that minimizes tire contact with the towed vehicle, reducing the likelihood of wheel damage and the need for replacements and repairs later on. Over time, this translates to a smaller overall environmental footprint for each recovery simply because the towed vehicle suffers less secondary damage and requires fewer interventions that themselves involve manufacturing and logistics.

The environmental dimension is also about the lifecycle of the tow truck itself. Modern fleets increasingly consider how materials, powertrains, and propulsion systems perform not only at the start of a shift but across thousands of cycles in a vehicle’s life. This is where design integration becomes a strategic priority. Environmental compliance is no longer an add-on feature; it is embedded in the choice of components, the arrangement of the hydraulic system, the routing of exhaust and cooling, and the selection of tires and suspensions. The net effect is a fleet that recovers more efficiently while consuming less fuel, emitting fewer pollutants, and producing less waste when components reach the end of their service life. The shift toward this integrated approach signals a broader policy move: regulators and manufacturers are recognizing that the recovery industry can set higher standards for resource stewardship if the equipment itself is built to be durable, maintainable, and less resource-intensive to operate.

For fleet operators, the practical implications of safety and environmental standards are as much about process as about parts. Compliance requires disciplined inspection schedules, meticulous maintenance, and rigorous training for drivers and technicians. Training is essential because the most advanced winch or the most robust stabilization system does not deliver its benefits unless the personnel using them understand the sequence of operations, the safety checks, and the proper way to secure loads under varying conditions. This is where the linkage to broader emergency response planning becomes important. Roadside recovery is inherently a high-stakes event, and the risk of accidents rises when teams are fatigued, inadequately briefed, or operating beyond the limits of their equipment. A robust safety culture, therefore, depends on clear protocols, ongoing competency assessments, and a shared language for signaling hazards and coordinating actions with other road users and authorities.

The regulatory landscape is not static, and operators must stay attuned to updates that refine or redefine best practices. Malaysia’s Tow Truck Technical Standards, for example, provide a living framework that evolves with new technologies and with a better understanding of the interactions between vehicle design, operator behavior, and highway safety. The November 2023 update is a practical reminder that safety is an ongoing discipline, not a one-time certification. It invites a proactive mindset: inspect more often, verify every anchor point, test every light, and rehearse every step of a recovery in a safe, controlled environment before performing it on a busy roadway. In the end, the goal is to deliver recoveries that protect the person at the scene, the person behind the wheel, and the other motorists who rely on the punctual clearance of obstructions and incidents.

The full tapestry of standards also resonates with a broader set of certifications and industry expectations. Many guidelines esteem not only the mechanical reliability of a tow truck but also its reliability as a service entity. Certifications such as ISO 9000 family standards underscore that a company’s internal processes—from supplier selection to maintenance scheduling to response protocols—must deliver consistent quality. In markets where CCC or CE marks are customary, those certifications reinforce a company’s commitment to safety, product integrity, and worker protection. And with emmissions considerations growing more stringent in many jurisdictions, Euro 2 and related standards are being threaded into the design criteria for engines and exhaust after-treatment systems. The converging effect is a fleet that is safer, more predictable, and less costly to own and operate across its life cycle.

For those who manage or build tow fleets, the regulatory and environmental narratives intersect with practical decision making in important ways. Procurement decisions must weigh not just the upfront price of a truck but the anticipated costs of compliance, maintenance, and downtime. The choice to prioritize a flatbed platform, for example, is informed by a combination of risk mitigation—minimizing damage to towed vehicles—and environmental considerations, such as reduced need for tire consumables and fewer road repairs triggered by improper wheel contact. Likewise, the decision to invest in multi-speed winches or advanced stabilization technology is guided by recoveries’ complexity and the likelihood of needing to achieve a safe outcome without prolonged engine idling. In settings where road rescue is a core function of public safety or fleet support, these investments can translate into tangible advantages: faster response times, fewer accidents at the scene, lower insurance costs, and a smaller environmental footprint at scale.

It is also worth noting the practical balance between regulation and operational flexibility. Standards aim to reduce ambiguity and unify expectations, but they must be adaptable to different road conditions, weather patterns, and vehicle configurations. A single approach cannot fit every scenario. As such, operators are encouraged to cultivate a culture of proactive compliance rather than box-ticking conformity. That means scheduling regular training refreshers, maintaining an organized maintenance log, and ensuring that the workforce has access to up-to-date manuals and reference materials. It also means embracing a mindset of continuous improvement—testing new equipment features in controlled environments, documenting outcomes, and sharing lessons learned with the wider community of tow operators. When standards are treated as a living practice rather than a static requirement, they become an engine for safer operations and more sustainable outcomes across thousands of recoveries each year.

The human element remains central to safety and environmental performance. A tow operation is as safe as the people who run it. That is why adherence to signage, lighting, and securing protocols is not a cosmetic matter but a core competency. It is the discipline that keeps workers out of the line of fire and reduces the likelihood of secondary incidents that compound risk—for example, a poorly secured vehicle shifting during transport or an apprentice failing to verify a connection before a lift. The most robust standards recognize this human factor and address it with clear procedures, accessible checklists, and realistic expectations about feasible operations under pressure. In this sense, the regulatory framework does not just constrain; it educates and elevates practice by making safety a visible, measurable, and repeatable behavior rather than a peripheral concern.

For readers seeking concrete, field-ready guidance, it helps to connect the standards to the daily realities of a fleet in operation. A maintenance plan that aligns with the latest rules will schedule periodic inspections of winches and hydraulic circuits, verify that all securing devices carry the appropriate load ratings, and ensure that lighting systems are tested for brightness and range under night-time conditions. It will also integrate environmental considerations into the maintenance routine, such as monitoring fuel efficiency indicators during recoveries, managing hydraulic fluid health to minimize leaks, and inspecting exhaust systems to ensure compliance with emission standards. In short, safety and environmental stewardship are best achieved when they are woven into the fabric of routine operations rather than treated as occasional checkups.

The chapter’s exploration also invites a practical reflection on how to navigate the evolving landscape with a sense of preparedness. Operators can benefit from scanning regulatory updates, maintaining relationships with regulators and reputable suppliers, and participating in peer networks that share case studies and best practices. In this sense, the industry gains from collective learning, where a well-documented recovery that demonstrates safe practices and responsible environmental handling becomes a reference point for others seeking to raise their own standards. The path forward is not merely compliance for compliance’s sake; it is about building a culture in which every tow job reinforces public safety, protects assets, and shows respect for the road on which all travelers depend.

For practitioners seeking a concrete starting point, consider examining resources that discuss essential strategies for fleet readiness and emergency response. As part of a broader ecosystem, these strategies offer practical steps for aligning day-to-day operations with the higher aims of safety and sustainability. Essential Fleet Emergency Response Strategies serves as a pertinent touchstone, illustrating how a fleet can integrate standard compliance into its practical workflows. While each fleet has its own constraints and opportunities, the underlying principles—clear roles, verified equipment, rigorous checks, and continuous improvement—resonate across contexts and help anchor the more technical, standards-driven aspects of this chapter in the lived experience of tow operators and road users alike.

As regulators and manufacturers continue to refine the technical standards, the guiding vision remains straightforward: tow trucks should enable safe, efficient, and responsible recoveries that minimize risk today and minimize environmental impact over the long term. The interplay between safety and environmental considerations is not a trade-off but an integrated design problem. The most effective fleets treat it as such, investing in robust equipment, disciplined maintenance, and a culture that treats every recovery as an opportunity to demonstrate excellence in service to the community. In a world where roads carry growing volumes of traffic and the stakes of every incident rise with pace, the commitment to safer, cleaner recoveries is not a marketing aspiration but a citizen’s obligation—one that begins with the trucks we build, the standards we uphold, and the decisions we make at the roadside when lives and livelihoods hang in the balance.

External reference: https://www.mot.gov.my/vehicles/tow-truck-technical-standards

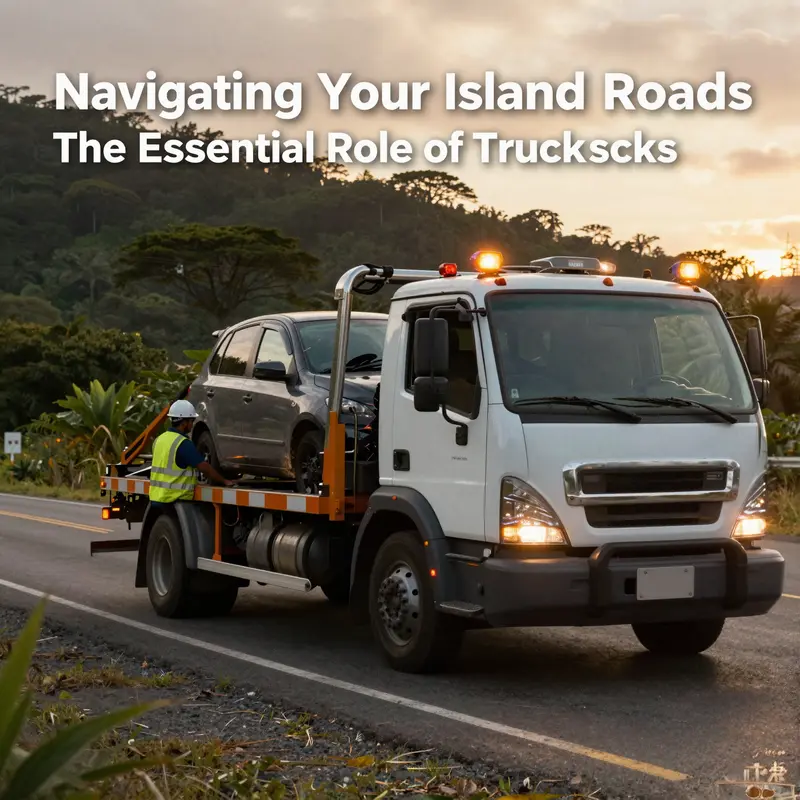

Tow Lines in Motion: The Vital Role of Towing Trucks in Roadside Rescue and Emergency Response

When the road turns lone and gravity is suddenly unkind to a traveler, a line forms not just in the traffic but in need. Towing trucks stand as more than road support; they are mobile first responders, capable of turning a stalled moment into a managed sequence that restores movement, safety, and confidence for those who rely on the system. This is not merely about hauling a vehicle from one point to another. It is about responsiveness, precision, and the orchestration of a complex set of skills and tools that allow a single truck to influence a broader network—police, emergency medical services, traffic management centers, and ordinary drivers who must continue their journeys with minimum disruption. The role of towing trucks in roadside assistance and emergency services is, in many ways, the quiet backbone of public safety in modern transport, a reminder that rescue often begins with the humble act of getting a vehicle unstuck from the edge of a highway or pulling it away from a potential hazard before chaos can escalate.

The effectiveness of towing operations rests on choosing the right equipment for the right moment, a decision that changes with the severity of the incident, the type of vehicle involved, and the surrounding environment. Wreckers, or recovery trucks, are designed to manage serious collisions where vehicles are damaged, situated off the pavement, or in positions that ordinary roadside tools cannot safely reach. Flatbed tow trucks, by contrast, provide a gentler yet equally controlled method of transport, letting the carrier strap, lift, or slide a vehicle so that delicate components—such as the undercarriage, body panels, or driveline—are protected during transit. In tight urban spaces or challenging terrains, specialty tow trucks equipped with hydraulic lifts or articulating booms extend the operator’s reach and flexibility. Each configuration has a distinct set of strengths, and the choice is driven not by preference but by the practical need to recover and transport with the least risk to people, property, and the vehicle itself. This capacity to tailor the response to the situation is one of the defining features of professional roadside rescue operations, where the margin for error is measured in minutes and in the possibilities foregone with every failed maneuver.

Behind the physical mechanics lies a philosophy of safety that governs every tow operation. A modern towing crew negotiates a scene the way a conductor manages a symphony: they assess hazards, establish zones, and coordinate with others to minimize exposure to passing traffic and to protect any injured or vulnerable occupants. The operator’s toolbox—winches, slings, chains, hooks, and mounting brackets—reads like a primer on restraint and stabilization, because securing a vehicle during recovery is as crucial as lifting it off the ground. The winch’s power is balanced by the restraint of solid anchor points and step-by-step checks that ensure the vehicle remains motionless until it is safely attached to the tow rig. The idea is simple and profound: control the risk, protect the asset, and deliver the vehicle to a safe location where it can undergo assessment, repair, or auction. In practice, this means that a tow truck driver must be as proficient at reading terrain and weather as at handling hydraulic systems and traction aids.

The operational core of roadside towing is embedded in the decision to deploy the appropriate type of vehicle. In the aftermath of a crash, the priority is to remove hazards from the roadway and to prevent secondary incidents. Wreckers can bring a damaged car to a controlled position on the roadside, where it can be evaluated by responders, opened to aid a casualty, or moved to a secure lot for later in-depth inspection. Flatbeds, meanwhile, are invaluable for preserving the integrity of cars that could suffer additional damage if dragged or bounced during transport. They allow the vehicle to be loaded in a manner that keeps the drivetrain and suspension aligned, an essential consideration for vehicles with potential structural concerns or with complex electronic systems that must be safeguarded from shock.

In urban settings and more complex recovery scenarios, specialty tow trucks bring a different kind of value. The hydraulic lift and adjustable booms enable technicians to reach vehicles that have come to rest in awkward positions—between barriers, on sloped shoulders, or in parking stalls where a traditional wheel-lift would be impractical. This adaptability extends the range of recoveries a single crew can manage in a single shift, reducing the need for multiple specialized units on a single incident and speeding up the overall response. The resulting efficiency is not merely a matter of convenience; it translates into fewer minutes spent in hazardous environments, less disruption to neighboring traffic flows, and a quicker return to normal roadway operations. Each of these benefits feeds into a larger public-safety objective: keeping roadways clear and predictable so that motorists can resume their journeys with confidence.

Beyond hardware, the human element remains central. A tow operator is trained to perform with caution and clear judgment. They must communicate with the scene’s stakeholders—law enforcement officers, fire and EMS teams, detour coordinators, and the drivers involved or nearby—so that everyone understands what is happening and why. This communication is not an afterthought but a core skill. It shapes the pace of the operation, informs the allocation of resources, and can determine whether a vehicle is removed promptly or kept in place until more information is gathered. The operator’s awareness of traffic patterns, weather conditions, and potential secondary hazards is matched by a humble commitment to procedural discipline: confirming the stability of the load, maintaining required safe distances, and never compromising the safety of passengers or bystanders. In this light, towing trucks perform as much as a support role in public safety as they do as mechanical specialists.

A modern approach to towing operations also hinges on how information flows from the moment a breakdown or crash is reported to the moment the vehicle is off the road and secured. Dispatch systems, GPS tracking, and real-time communication tools have transformed what used to be a reactive service into a proactive networked operation. The dispatcher can track unit locations, estimate arrival times, adjust routes to avoid congestion, and coordinate with other responders to ensure the scene is managed efficiently and safely. This integrated workflow reduces the likelihood of miscommunication and helps responders anticipate needs—an essential advantage when traffic volumes are high or when incidents require multi-agency collaboration. The end result is a smoother, faster, and safer incident management process that benefits not only the drivers involved but the traveling public at large. In this sense, towing trucks are not solitary fixers but nodes in a larger web of emergency response and traffic management.

Safety and compliance form another layer of importance in towing operations. Tow trucks must adhere to safety standards and environmental regulations that ensure responsible operation and dependable performance. This translates into robust maintenance schedules, verified safety procedures, and environmental stewardship that minimizes emissions and reduces the risk of fuel spills or other hazards during recovery. Operators are trained to perform risk assessments before, during, and after a tow, and to use PPE appropriate to the scene. They script a recovery plan in the same way a flight crew would prepare for a challenging takeoff: anticipate what could go wrong, have contingencies ready, and execute with discipline. Even the most routine tow requires this mindset because the consequences of a misstep are magnified by moving traffic, weather, or the presence of injuries. The result is a service that is consistently reliable, adherent to best practices, and respectful of the surrounding community as it works toward restoring normalcy.

The broader impact of towing trucks on road safety and mobility should not be underestimated. When a breakdown occurs in the middle of a congested highway or during a high-speed incident, a well-placed tow unit helps to reestablish lanes and reduce the risk of secondary impacts. The swift removal of disabled vehicles from the travel path minimizes congestion and supports economic activity by shortening the duration of road closures or detours. The vehicles involved get the attention they deserve, not through sensational visibility but through steady, capable intervention that allows responders to focus on securing the scene and stabilizing the situation for medical or investigative teams. In many ways, the presence of a tow truck at the scene sends a signal of control and competence, the reassurance that help has arrived and that the next steps will be managed with care. This perception matters; it reinforces public trust in emergency response systems and underscores the essential partnership between everyday road users and those who serve in the line of duty.

Looking ahead, the evolution of towing operations is likely to be shaped by ongoing advances in technology and data-driven management. More sophisticated onboard systems can monitor load dynamics, stabilize vehicles with greater precision, and communicate with other responders about evolving conditions on the scene. Telematics and cloud-based dispatch platforms will continue to shrink the gap between incident detection and effective response, enabling a more proactive stance where potential bottlenecks and hazards are anticipated before they manifest. As fleets grow more interconnected, towing units will become even more capable of supporting dynamic incident command and recovery planning, drawing on historical data and predictive analytics to optimize resource allocation and route selection under varying levels of traffic and demand. The end result will be a more resilient roadside ecosystem where towing trucks play an ever more integral role in public safety, not merely as last-minute fixers but as essential, anticipatory partners in saving time, reducing risk, and preserving the flow of life along our highways.

This integrated approach finds practical expression in essential fleet emergency response strategies. essential fleet emergency response strategies.

To readers seeking a deeper technical understanding of the equipment and its applications, external resources offer a comprehensive overview. For a deeper technical overview of tow equipment and its applications, consult the following external resource: https://www.towtruck.com/technical-overview-best-tow-trucks-specifications-and-applications. This reference complements the narrative by outlining the specifications, capacities, and design considerations that govern real-world recoveries, highlighting how engineers and operators translate theory into safe, effective practice on crowded roadways.

Final thoughts

Towing trucks are indispensable assets to our island communities, ensuring safe transportation, compliance with safety regulations, and responsive assistance during emergencies. Their lifting capabilities and robust construction allow them to handle various vehicular challenges, whether it’s a small car or a commercial fleet vehicle. As auto repair shops, car dealerships, property managers, resort operators, and fleet operators integrate these trucks into their operations, they not only enhance their service offerings but also contribute to a safer, more efficient driving experience for everyone. Embracing the value of towing trucks is recognizing their crucial presence in the symbiotic relationship between vehicles and road safety.